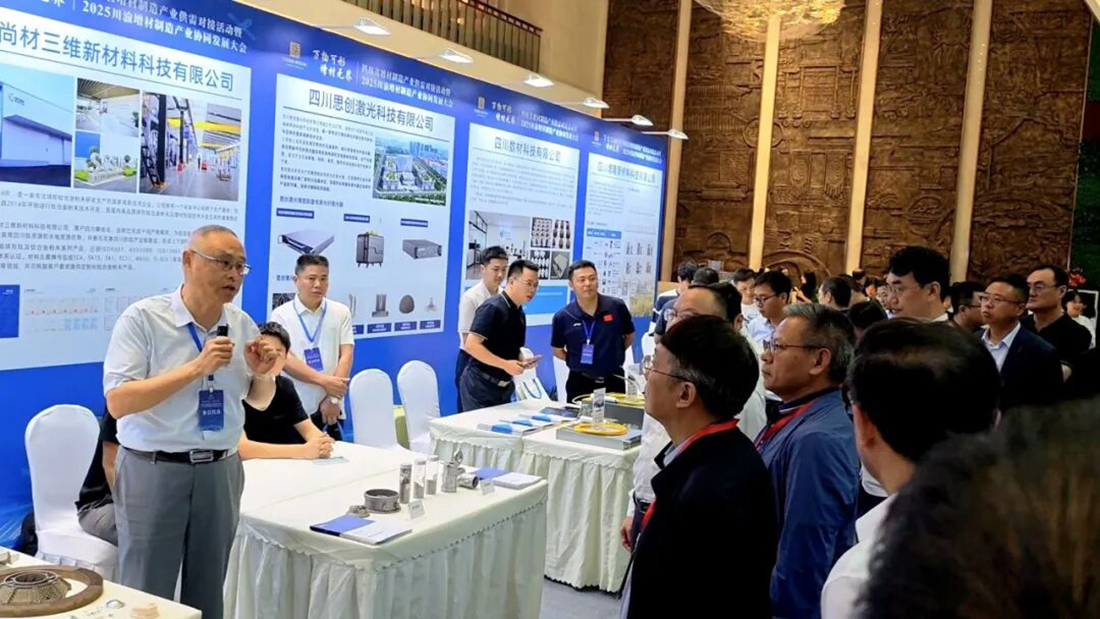

【News source: Additive Manufacturing in Sichuan Province】

On-site Interview with Chengdu Keningda Materials Co., Ltd.

Interviewee: Professor Li Ning, Chengdu Keningda Materials Co., Ltd.

Could you please briefly introduce the development history of your company, your main business, and your position in the additive manufacturing industry chain (materials, equipment, software, services, applications, etc.)?

Li Ning: Chengdu Keningda Materials Co., Ltd. was established in 2004. Our main business includes advanced metal materials, special ceramics, brazing processing, and the production of selective laser melting powders for 3D printed dentures. Our company's industrial chain mainly focuses on the denture processing stage. Our 3D printing powders (including cobalt-chromium alloy powder and titanium alloy powder) are used for denture printing, transforming the traditional dental casting process into additive manufacturing.

This transformation has the following advantages: First, it achieves green manufacturing with no environmental pollution. Second, it adopts digital manufacturing with high precision, which is not dependent on the craftsmanship and mood of artisans. West China School of Stomatology of Sichuan University enjoys a high reputation in the international dental field. Its digital dental industrial chain covers clinical dental scanning, denture design and manufacturing, etc. Among them, denture manufacturing requires the use of our company's 3D printing powder and related laser selective sintering equipment. In addition, it also includes 5G + manufacturing based on the Internet. The development trend of this industrial chain is to set up printing centers in some major cities across the country and even the world to receive data provided by clinics and processing plants for printing, and then complete post-processing for further processing by processing plants and clinical application.

May I ask what are the core advantages of the company in the research and application of additive manufacturing technology?

Li Ning: Currently, our company has obtained 10 related invention patents and obtained 2 Class III registration certificates and 5 Class II registration certificates issued by the National Medical Products Administration. In terms of additive manufacturing technology, we mainly adopt vacuum gas atomization powder-making technology. The core advantage lies in the high fine powder collection rate, high sphericity, low hollow powder content, and high tapped density. This is attributed to the company's unique vacuum gas atomization spray disk technology, also known as the tight coupling supersonic jet technology. The breakthrough of this process solves the key problems of gas atomization.

In addition to dental material applications, the company is also involved in the field of special ceramics and vacuum brazing and sealing technology. According to the demands of central enterprises such as aerospace, nuclear power, weapons, and electronics, we customize special electrodes and components with high voltage, high water pressure, and large pulses to meet the requirements of various models.

Could you please tell me what the main goals of your company are for participating in this Sichuan Additive Manufacturing Industry Supply and Demand Matching Conference? What resources or partners do you expect to connect with?

Li Ning: 1. Conference experience and supply and demand matching. I hope that the association and the government can integrate the industrial chain within Sichuan from the material and equipment to the application level. As a major military industry province, Sichuan has many aerospace and nuclear industrial enterprises and is one of the main application areas for additive manufacturing. Currently, compared with coastal areas, there is still room for improvement in raw materials and printing equipment in our province. I suggest that the association hold more enterprise matching activities in the future.

2. Construction of an industrial system ecosystem. I hope the government can provide policy support in all aspects of building an innovation chain to an industrial chain. In terms of talent cultivation, support universities and vocational and technical colleges to carry out talent cultivation work. Jointly organize technological breakthroughs, accelerate market cultivation and application promotion. The application of technological achievements from universities and research institutes is the key to the development of additive manufacturing. These measures aim to enable the research teams of universities to step out of the campus, face engineering applications, and transform research achievements into actual products to achieve economic and social value.

Could you please tell me what your company's plans are for the development of additive manufacturing in the next 1-3 years? What are the key areas of expansion?

Li Ning: Our company's additive manufacturing business will mainly focus on two expansion directions in the next 2-3 years. First, leveraging our deep foundation in dental 3D printing materials, we will promote our 3D printing powder products to the international market (including Russia, Central Asia, the Middle East, Southeast Asia, India, South America, and Europe, etc.) and establish the international brand of "Huaxi Powder". Second, we will apply our existing technology to print parts for military and aerospace fields such as high-temperature alloys, which requires cooperation with domestic related enterprises like Luzhou Hanfei.

In my opinion, the future development trends of additive manufacturing mainly lie in the following aspects: biological additive manufacturing can use living ink to print biological organs that can be implanted in patients through inkjet printing technology; and the transformation of traditional processing industries through additive manufacturing technology, such as using inkjet printing to cast sand molds.

Finally, I expect that through the cooperation between numerous military enterprises in Sichuan and units related to additive manufacturing materials, equipment, applications, and testing, the additive manufacturing industry in Sichuan will have a promising future.